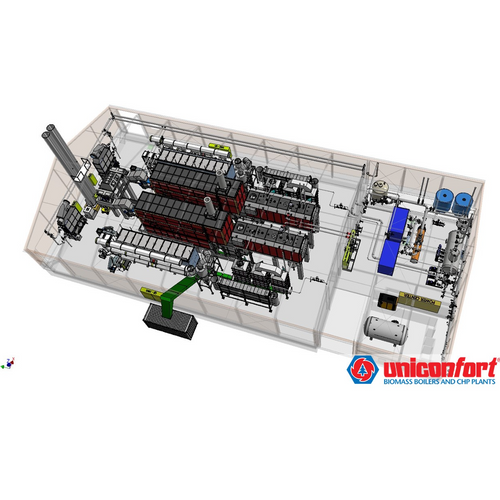

STEAM PLANT

Uniconfort’s biomass steam plants represent the forefront of sustainable energy technology, providing efficient and environmentally friendly solutions for industrial applications. These advanced systems harness the power of renewable biomass such as wood pellets, agricultural residues, or dedicated energy crops, to produce steam and heat, offering a compelling alternative to traditional fossil fuels.

At the core of Uniconfort’s biomass plants is their cutting-edge combustion technology, designed to optimize fuel efficiency and reduce emissions. The plants incorporate sophisticated systems for air and heat management, ensuring complete combustion and minimizing emissions. This results in a significantly lower environmental footprint compared to conventional energy sources.

One of the key features of Uniconfort’s biomass steam plants is their versatility. They are capable of handling a wide range of biomass feedstocks, making them adaptable to local resource availability and varying energy needs. The plants are engineered for high reliability and durability, with components that are built to withstand the rigorous demands of continuous operation while minimizing maintenance requirements.

Uniconfort emphasizes innovation and customization in their biomass solutions. Each plant is tailored to meet specific client needs, whether it’s for a large industrial facility, a district heating system, or a smaller commercial operation. This bespoke approach ensures optimal performance and cost-effectiveness, providing clients with a robust and scalable solution for their energy demands.

In addition to their technical excellence, Uniconfort’s biomass steam plants contribute to a greener future by reducing reliance on fossil fuels and lowering greenhouse gas emissions. By investing in these state-of-the-art systems, organizations can achieve energy independence, reduce operational costs, and support a sustainable energy transition.

Categories

- Processing

- General Processing Technology

)

)

)