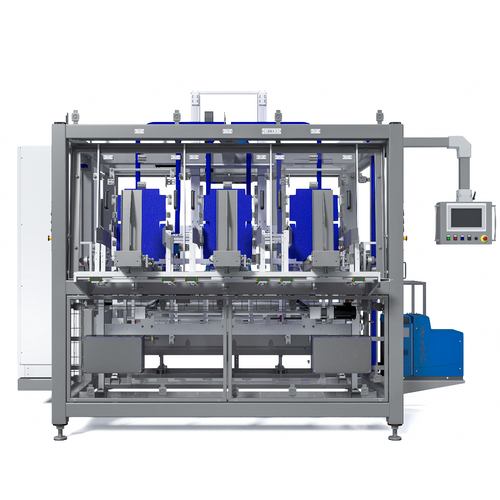

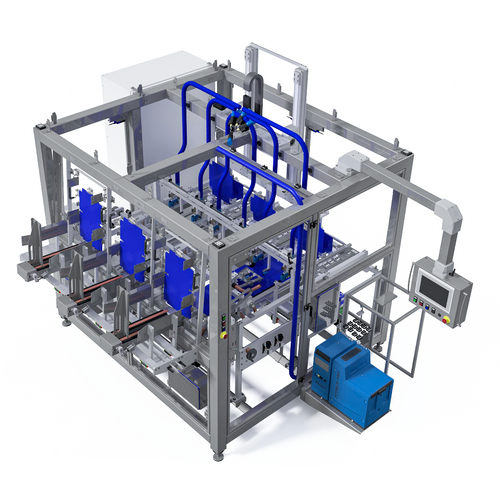

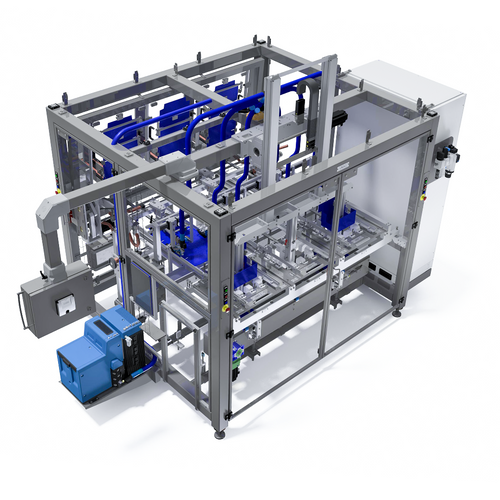

Box Erector

Available in different configuration (single, double or multiple forming heads) according to the required capacity, the mechanical movements are

servo-driven and allow for optimisation of the

various operations. The blanks are picked up from

magazine, then placed on a centring system with

glue spraying before being erected.

A machine designed to handle a large variety of size with a high degree of reliability and reduced

changeover times. Adaptable to any kind of

production environment and satisfying any

ergonomic and hygienic requirement, the machine is also available in a stainless steel configuration.Main Features:

- High speed servo-driven machine

- Blanks magazine(s) with friction-belt

- Servo-driven blank picking

- Servo-driven blank centring system

- Automatic Hot Melt gluer

- Forming tool for box glued in 4 corners

- Plunger dedicated to each format base

- Machine adjustable in all sections by

means of handwheels

- Safety guardings with interlocked sensors

- Electrical cabinet (with PLC, servodrives…)

- Painted steel structure

- Lexan safety doorsCapacity:

- 40 boxes/min single head*

- 80 boxes/min double head*

- 100 boxes/min triple head*

- 120 boxes/min quadruple head*

* Depending on box dimensionsAvailable options:

- Stainless steel construction

- Motorized setting on magazine, guides,

guns position

- Extended magazine length for increased

autonomy

- Automatic hot melt feeder

Categories

- Packaging Equipment, Containers & Supplies

- Packaging

)

)

)