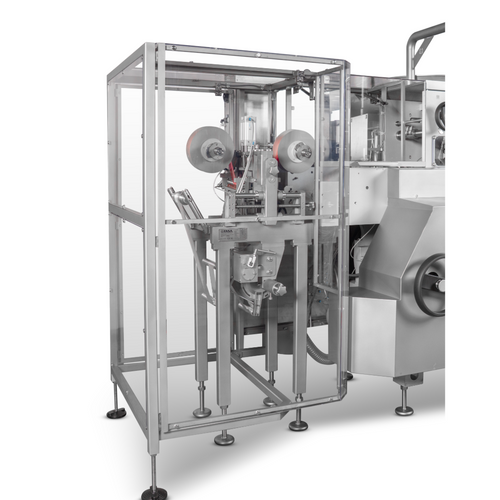

ARU - Processed cheese filling and wrapping machine

Processed cheese filling and wrapping machine is ARU an automatic packaging machine for foiling of processed and cream cheese with aluminum foil with or without easy opening system and labeling.

Processed cheese into consumer’s size portions.

Applicable products: processed cheese, cream cheese.

Type of dosing – volumetric.

Double jacket (heating) 85l hopper with agitator.

Machine’s output: up to 50 packs/ min.

Sizes of package: 15-100 g (one size).

Product input temperature: +65….+75 °C.

Shapes of package: rectangular, square.

Packaging materials: coated aluminum foil; aluminum foil laminate with tear strip applicator (optional).

Heat-sealed package from coated aluminum foil.

Tear strip material: tear tape heat sealable with aluminum foil.

Labelling device: 1 side label, 3 sided label, without label.

PLC and HMI with Touch Screen.

Foil cuts collecting system.

Machine safety covers.

Options

Tear strip applicator

Optional tear strip applicator ARU-10 can be attached to the new or used FASA ARU. Process of integrating the easy opening tear strip goes at the beginning of the briquette forming sequence. It is done by cutting-of tear tape film from two rolls and heat-sealing shaped stripes to the aluminum foil creating a user-friendly easy opening solution.

Labelling device

There are two types of paper label: one side label (placed on top of the package) and three-sided label (covers three sides of the package). Paper label is pre-printed with full information about a product. Both types of paper label is glued on a foil package.

Centering device with photocellPhoto eye for centering of the label is available. It reads a photo mark on the packaging material and cuts it accordingly so that the label is centered.

Categories

- Packaging Equipment, Containers & Supplies

- Filling & Sealing

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)